Product Overview

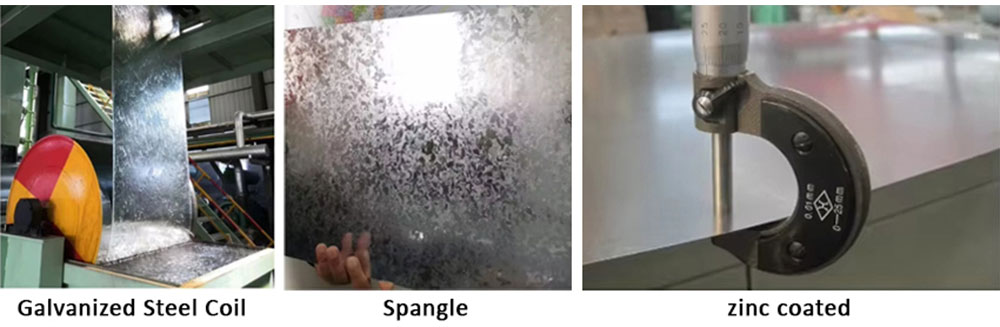

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

Product Description

Corrugated Galvanized Roofing Steel Sheets are a fundamental and highly durable building material, widely recognized for their strength and corrosion resistance. Manufactured from high-quality steel coils that undergo a hot-dip galvanizing process, these sheets are coated with a protective layer of zinc. The distinctive corrugated profile adds significant structural rigidity, allowing them to span longer distances and withstand heavy loads. This classic solution is ideal for industrial, agricultural, and utility buildings where robust performance and cost-effectiveness are paramount.

Technical Parameters

Roofing sheet / Corrugated Steel Sheet | |||

Standard | AISI,ASTM,GB,JIS | Material | SGCC,SGCH,G550,DX51D,DX52D,DX53D |

Thickness | 0.15—0.8mm | Length | 16-1250mm |

Width | Before Corrugated:665-1025m | ||

After corrugated:750-1200mm | |||

Color | Top side is made according to RAL color, Back side is white grey in normal | ||

Tolerance | +-0.02mm | Zinc | 30-275g |

Weight | |||

Top Panit | 8-35 Microns | Back | 3-25 Microns |

Panit | |||

Basal Plate | GI GL PPGI | Normal | Wave Shape,T Shape |

Roof | |||

Shape | |||

Certification | ISO 9001-2008,SGS,CE,BV | MOQ | 25 TONS (in one 20ft FCL) |

Delivery | 15-20 days | Monthly Output | 15000-20000 tons |

Package | seaworthy package | ||

Surface treatment | unoil,dry,chromate passivated, non-chromate passivated | ||

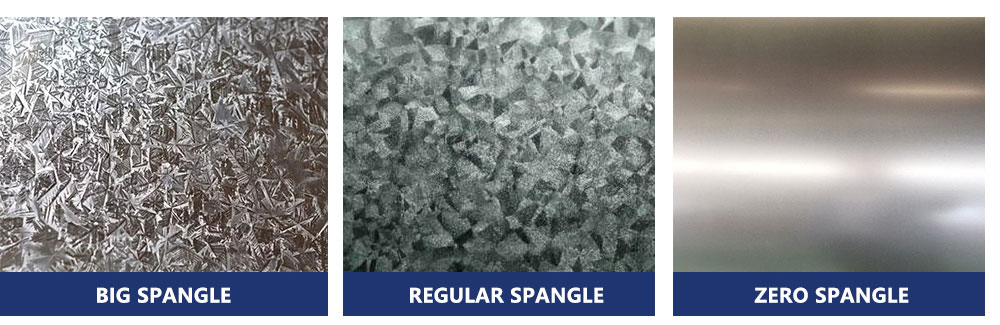

Spangle | regular spangle,minimal spangle, zero spangle,big spangle | ||

Payment | 30%T/T in advanced+70% balanced | ||

Key Features & Highlights

Superior Corrosion Resistance: The hot-dip galvanized zinc coating acts as a sacrificial layer, providing long-term protection against rust and corrosion, even in harsh and humid environments.

High Structural Strength: The corrugated profile gives the sheets exceptional load-bearing capacity and resistance to wind uplift, making them suitable for regions with heavy snow or strong winds.

Long Service Life & Durability: The combination of strong steel and a robust zinc coating ensures a long service life with minimal maintenance, offering excellent value over time.

Cost-Effective Solution: As one of the most economical roofing and cladding options available, it provides reliable protection for a wide range of structures without a high initial investment.

Versatility & Wide Application: Its simple, functional design makes it suitable for a vast array of structures, from warehouses and factories to farm sheds and fences.

Application field

Industrial Buildings: Roofing and wall cladding for factories, warehouses, and workshops.

Agricultural Buildings: Sheds, barns, poultry houses, and storage facilities for equipment and crops.

Utility & Infrastructure Structures: Canopies, carports, and temporary site shelters.

Fencing & Enclosures: For security perimeters and animal pens.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.