Product Overview

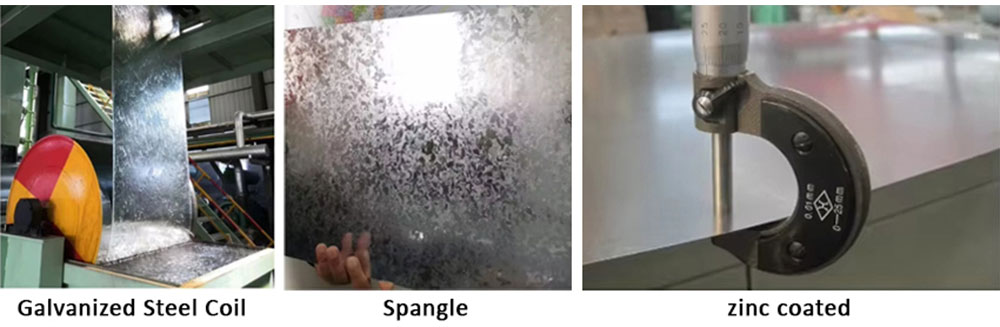

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

PVDF Electrostatic Powder Coating Color Board represents the pinnacle of performance for powder-coated metal. Utilizing a premium Polyvinylidene Fluoride (PVDF) resin-based powder, this product offers weatherability and durability that rivals and even surpasses its liquid PVDF counterparts. The electrostatic application and thermal curing process result in an ultra-durable, seamless finish with exceptional resistance to UV radiation, extreme temperatures, and chemical attack. It is the ultimate specification for high-end architectural projects, marine environments, and any application demanding maximum longevity and color stability.

Product Description

Electrostatic powder-coated boards utilize internationally advanced electrostatic spray technology to achieve one-time coating formation. The fully automated production line ensures a green and highly efficient manufacturing process. Both the equipment and coating materials hold multiple national invention patents, completely revolutionizing traditional color-coated board production methods. This innovation effectively addresses the chronic issues of heavy paint pollution, low operational safety, and high energy consumption inherent in conventional processes.

The powder coating is formulated with various high-performance eco-friendly materials, containing no solvents and producing zero VOC emissions. It demonstrates significant advantages in energy efficiency, safety, and environmental protection while exhibiting excellent adhesion, weather resistance, and corrosion resistance. Our company employs high-molecular powder coatings that utilize the principle of electrostatic adsorption to ensure uniform and firm adhesion of the powder to the substrate surface.

Through high-temperature curing, a dense coating is formed that fundamentally overcomes the drawbacks of pollution, safety concerns, and energy waste associated with traditional processes. The comprehensive performance of our powder coating significantly surpasses that of conventional paint coatings, providing superior durability and protection while maintaining environmental sustainability throughout the product lifecycle.

Different substrates such as galvanized,aluminum zinc coated,galvanized aluminum magnesium coated,cold plate,stainless steel,aluminum plate,etc.can be selected based on factors such as the purpose,structural forming.and usage environment ofthe powder coated plate.Materials such asDX51D,DX52D,DX53D,S350GD,S550GD,etc.can also be selected as needed

Specifiction

| Base Material | Aluminum Alloy (e.g., AA3003, AA5005) | Standard Width | 1000mm - 1300mm |

| Coating Type | PVDF Resin-Based Powder | Gloss Level | Typically Matte to Satin |

| Coating Thickness | 70 - 90 μm (typical) | Pencil Hardness | ≥ H |

| Standard Thickness | 0.6mm - 4.0mm | Salt Spray Resistance | > 1000 hours without corrosion |

Key Features & Highlights

Unmatched Super-Weatherability: PVDF powder coating provides the highest level of resistance to UV degradation, ensuring minimal color fade (ΔE<5) and chalkiness over decades, even in harsh, sun-drenched environments.

Superior Corrosion & Chemical Resistance: Offers excellent protection against salt spray, industrial pollutants, and acidic/alkaline chemicals, making it perfect for coastal and industrial applications.

Self-Cleaning & Low Maintenance: The smooth, non-porous surface and excellent anti-stick properties promote the "rain-wash" effect, where dirt and contaminants are easily washed away by rainfall.

Excellent Mechanical & Thermal Properties: Maintains film integrity and adhesion under significant impact, bending, and exposure to extreme temperature fluctuations (-40°C to 120°C).

Long-Term Aesthetic & Financial Value: The extended service life, minimal maintenance needs, and guaranteed color performance provide an outstanding lifecycle cost, making it a wise investment for premium projects.

Application field

High-Performance Architectural Facades: Curtain walls, roofing, and cladding for skyscrapers, museums, and airports.

Marine & Coastal Architecture: Building exteriors, yacht fittings, and offshore structures exposed to salt-laden air.

Specialized Industrial & Chemical Plants: Cladding for buildings and equipment requiring resistance to corrosive fumes.

Premium Residential & Luxury Projects: High-end residential roofing, fencing, and exterior decorative elements.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

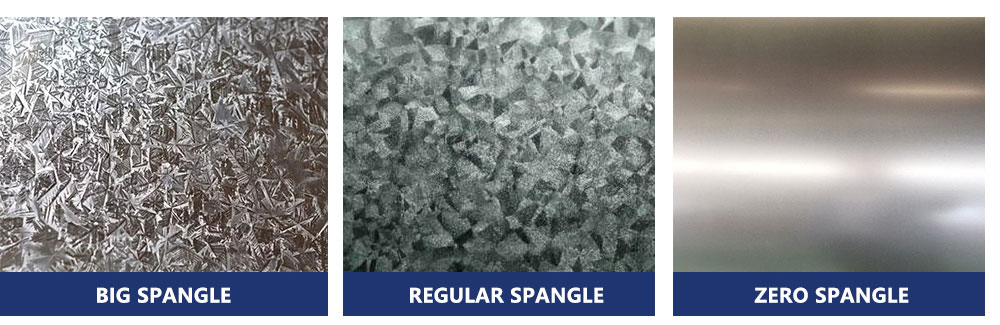

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.