Product Overview

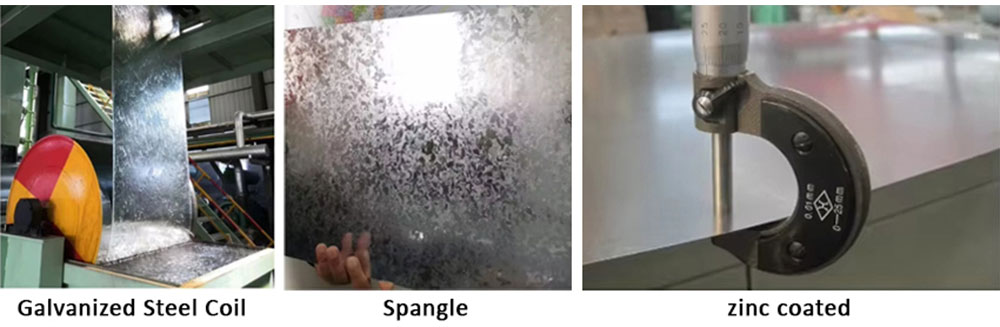

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

PVDF Coated PPAL represents the premium tier of pre-painted aluminum, utilizing a Polyvinylidene Fluoride (PVDF) resin-based coating. Renowned for its exceptional weatherability, this coating system delivers superior performance in harsh, corrosive environments. PVDF coatings exhibit outstanding resistance to UV radiation, chemicals, and pollution, ensuring minimal color shift and chalkiness over decades. It is the specified choice for high-profile, long-life architectural projects demanding maximum durability and aesthetic permanence.

Product Description

Our color-coated aluminum panels utilize PVDF-based fluorocarbon coatings, formed from homopolymers or copolymers with exceptional chemical bond stability. These coatings deliver outstanding mechanical strength, abrasion resistance, and long-term UV durability. Applied via roller coating or spraying followed by high-temperature curing, they are available in both traditional and nano-enhanced versions. Since their 1965 debut, they have become the global standard for curtain walls, now backed by over 20-year warranties. A 12-year Florida exposure study confirmed 30–80% superior durability versus alternatives, ensuring reliable performance under extreme conditions.

Specifiction

| Base Material | Aluminum Alloy (e.g., AA3003, AA5005) | Standard Width | 800mm - 1600mm (or as per coil) |

| Coating System | Chemical Pretreatment + Primer + 70% PVDF Resin Topcoat | Color & Gloss Options | Extensive range, including metallic colors. Excellent color consistency. |

| Total Coating Thickness | ≥ 25 μm | Pencil Hardness | ≥ HB |

| Standard Thickness | 0.5mm - 4.0mm | Salt Spray Resistance | > 1000 hours without base metal corrosion |

Key Features & Highlights

Superior Weatherability & UV Resistance: The PVDF resin is inherently resistant to solar radiation, guaranteeing exceptional long-term color retention and resistance to chalking, making it ideal for sun-exposed facades.

Excellent Chemical & Pollution Resistance: Withstands attack from acidic rain, alkaline pollutants, and industrial fumes, maintaining its integrity and appearance in urban and coastal environments.

Self-Cleaning Property: The smooth, non-sticky surface and resistance to static buildup allow rainwater to effectively wash away dirt and pollutants, reducing maintenance costs.

Outstanding Mechanical Durability: Offers excellent resistance to scratching, abrasion, and impact, ensuring the surface remains pristine during handling, installation, and throughout its service life.

Long-Term Value & Investment: The extended service life and minimal maintenance requirements of PVDF-coated aluminum provide a lower total cost of ownership over the lifespan of a building compared to standard coatings.

Application field

High-Rise Building Curtain Walls & Facades: For iconic commercial, residential, and public buildings.

Architectural Roofing & Cladding: Premium residential roofing, airport terminals, and stadiums.

Marine & Coastal Structures: Building exteriors in harsh salt-spray environments.

Renovation Projects: Ideal for retrofitting old buildings with a durable, modern, and long-lasting new skin.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

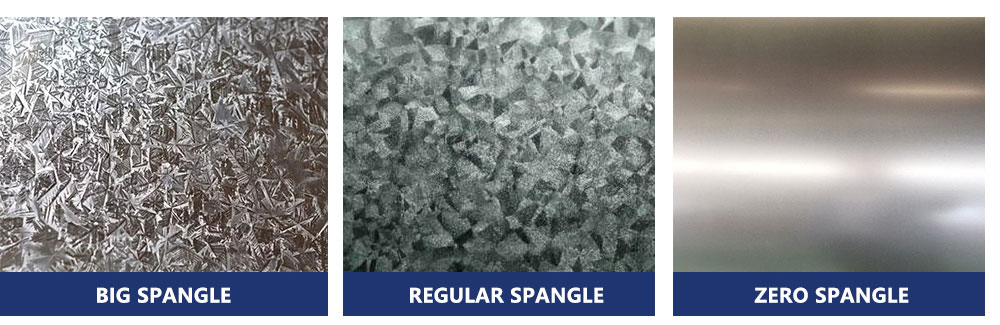

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.