Product Overview

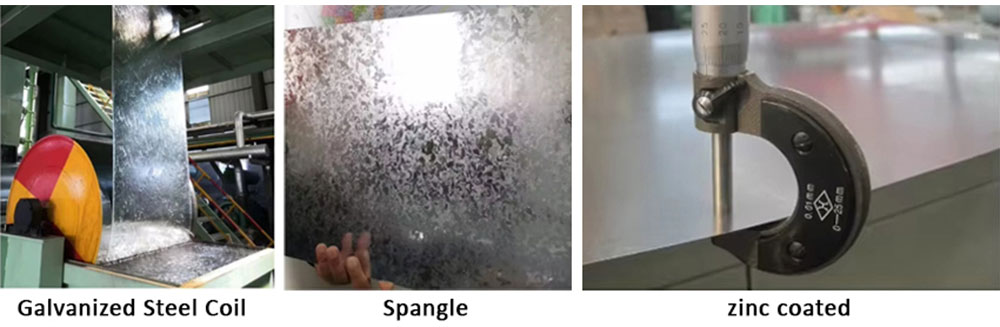

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

INTRUCTION

Pre-painted Galanized steel refers that the surface pretreatment of base plate,covering one layer or two layers(more than two layers when nec- essary)organic coating on the surface with the method ofcontinues roller coating;and then conduct drying and solidiying.

Compared with single part spraying or brushing on the surface of forming metal,the costing quality of color-coated stel plate is more uniform, table and ideal.Pre-painted stel plate is chat=racterized of excellent decoration, moldablity corrosion resistance,strong caating adhesive forceand can keep the novel luster for a long time. Since color-coated steel plate has not only mechanical strength and shaping performances of steel plate,but also favorable decoration and corrosion resistance of organc material.It can realize highly effective construction and husband the energy:prewent the pollution caused by second process and other favorable economic benefits.Currenty it has become the ideal composite materia in con struction,household appliance light industry,machinery and electronics and other industries.

Product Description

The substrate of the color coated steel sheet is a cold rolled substrate,a hot-dipgalvanized substrate and an electrogakanized substrate,and the substrate of the colored aluminum plate is an akuminum plate.

The types of coatings ean be divided into:

Polyester (PE)has good adhesian,a wide range of formaility and outdor durability and moderate chemical resistance.The servic ife is 7-10 years.

STcon modified polyester (SMP),which has good hardness,wear resistance and heatresistance,good external durability and non-powderability.and limited gloss retention and flenibility.The service life is 10-15 years.

High weathering polyester (HDP,excelent U resistance,high durability,and is main properties are between pobyester and fuorocarbon.The service life is 10-12 years.

Polyvinylidene fuoride PVDF)has good formabilityand color retention,excellent outdor durabily and powdering,solvent resistance,and lim- ited color.The service life is 20-25 years

The surface state of color-coated stel shets can be divided into coated sheets,embossed sheets and printed sheets.Color-coated stel sheets are widely used in construction appliances and transportation industies,For the construction industry,thy are mainly used in ste structures,a- ports,warehouses andfreezers.Roof walls and doors for industrial and commercial buildings.

Wide range of uses for color coated steel sheets

Excellent weather resistance,corrosion resistance,high processability and beautiful appearance,with its excellent quality incuding construction interior and exterior materials,household products and electrical appliances,etc.

Product introduction of eolor coated steel

The color cated steel plate is made ofho-dip galvanized steel shet,which is subjected to mulfi-stage degreasing,cleaning and chmical con- wersion treatment,and then the stel strip is continuously coated,cleaned and baked continuously.Color coated steel has eucellentdecorative,an t-corosion,weather resstance,fullcolor,brightcolor can be maintained for more than 15 yearsl.long service lile (30-50 yers),wide use,and has become widely used in the construction industry in the world today.Preferred product.

Main use of color coated steel

Construction ofvils,industrial plants,commercia,residential,warehouse,coldstorage,ship warehouse,interior wall materials,ceiling materials, partitions,fre doors,window panels,signboards,fuel/gas bolers,rice barrels,original building plus layers,etc.It can be fiexibly applied to any building .

Product advantages of color coated steel

Non-poluting.oconomicl:It can reduce investment costs and staf of finshing equipment shorten working hours,improve work and improwe economy.In the future,because of raising awareness of emwironmental protection and strengthening industrisl control color steel plates are more needed.

COLOR DISCRIMINATION MAPS

The substrate of the color costed steel plate is a cold rolled suostrate,a hot-dip galvanized substrate and an electrogalvanized substrate.The coatingtypes can be divided into plyester,silicon modified polyester,poyvinylidene fluoride and plastisolThe surface state of color-costed steel sheets can be divided into coated shets,embossed shets and printed sheets.Color-coated stel shets are widey used in construction appllances and transportation industies.Forthe construction industry,they are mainly used in steel structures,airports,warehouses and freezers.For roofs and dors of industial and commercial buildings,there ae fewer color stel plates for civil building.It differs from plastie stel in the composition of the material.The magnet can be sucked.

2/2 COATING STRUCTURE

Specifiction

Size(mm | ||||

Thickness | 0.12-1.5M4 | Easeplate | Hot-dipped galvanized sel sheet Hot-dipped auminum zinc steel sheet | |

width | 700-1250MM | Color | RAL card no.or color samples | |

Coating | Two coatingand two drying | Top coating | 5+10-20UM | |

Top side | Two coatng and two drying | Back coating | 5-12um | |

Back side | one coating and one | COIL ID | 508/610MM | |

| 60% Glossy | tall | >70 | Pancil hardness | >>2H |

| Chinese | 40-70 | |||

| low | <40 | |||

Specifications and features:

1.Light weight:10-14kg/square meter,oquhalent to1/30 of the brick wall

2.Thermal insulation:Thermal conductivity of core materiat A<=0.041w/mk.

3.High strength:It can be used as a load-bearin structure for ceilings,bending and compresion;general houses do not use beams and clumns.

4.Bright color no need for surface decoration,color galvanized steel ant-corroion Layer is maintained for 10-15 years

5.Flexible and quick installation:the construction period can be shortened by more than40%

6.Oxygen index:(CD)32.0(provincial fire protection product quality inspection station).

Application field

Application in electrical appliance

Refrigratorsdisplay cases of frozen foodswashing machines,electric ovens pan recorders,amplifers,auto booths alr-conditioners,electronic computers duplicating machines,switch cabinets,instrument cabinetselectric fans,dust collectorsete.

Applications in the transportation industry

Car ceilings back boards,boardinginterior decorating plates,vehicle shells,trunk plates,passenger cas,instrument plates shels of control con- soles trollystramcars,trainceilings,paritions,inner was,dors,iner devices of wehicle,color prtitions of steamship,ship furmiture and fiorscon- tainers,atc

Applications in the sheet metal processing and furniture

Ventilation heating stove,petroleum furnaces,shellof water boilers,shell of electric water heaters,counters,racking ,signboards,bindng lighting lamps,wardrobes,sofas,chairs,lockers,file cabinets,book shelves,etc,

Applications in other aspects

Shells of musical instrument,electronic organsweight counts,dustbins gauges.instrument plates.shell f vacum flasksphotographic equipment.

typewriters,bulletin boards,watches lighters,packing containers,etc

Technical indicators

1.Base plate

According to Jis G3302 or GB/T2518 standards

Zinc coating:Z30 、Z40 、Z60 、ZB0,AZ30,AZ40,AZ60,AZ80

2.Coating

Pre-pinted steelsheetsupply the gods acord with the morestrit internal cntrel standard,which is established according to national standard.

Paints variety:Polyester for internal and external use,slicon modifed polyester,highly durable polyster,epox nesin,alkydethylene resin,polypr oplylene,polyvinylidine fluoride and fluorocarbon.

Coating colorit is selected according to customer requirements.

Coating structure:2/12/2

Coating thickness:Top sides 20μm,back side is 5-15μm,or it is selected according to customer requirements.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

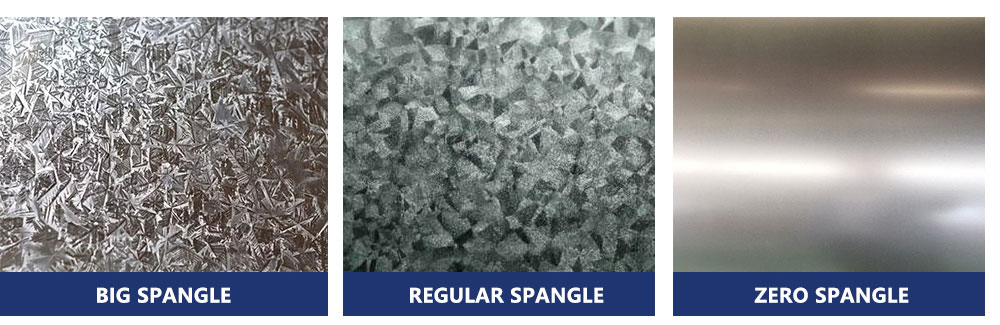

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.