Product Overview

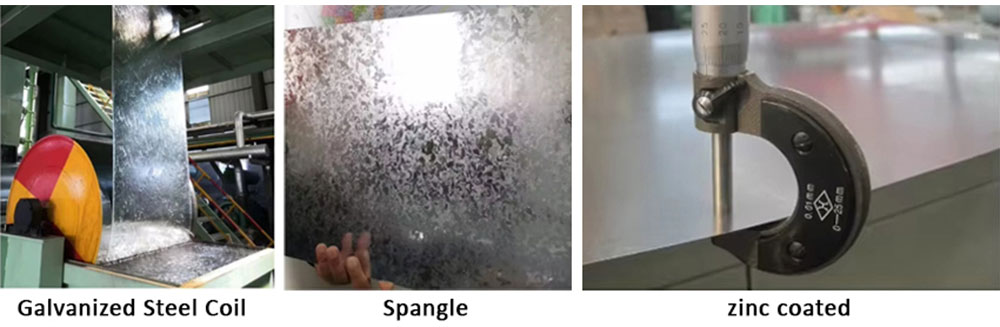

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

PE Coated PPAL is a versatile and economical pre-painted aluminum product, where the aluminum substrate is coated with a durable Polyester (PE) paint system. This coating offers a excellent balance between cost, color flexibility, and good mechanical properties. It provides a sleek, uniform finish with good resistance to fading and weathering, making it a popular choice for a wide range of indoor and moderate outdoor applications where extreme environmental conditions are not a primary concern.

Product Description

Pre-painted aluminum steel base plate specifications: thickness 0.15-1.5mm, width 500-1250mm. The PVDF fluorocarbon coating features robust fluorocarbon chemical bonds, delivering exceptional weather resistance, impact resistance, and UV stability. After high-temperature curing, the coating forms a dense protective layer. Available in traditional and nano-enhanced types. Since its first application by Pennwalt Chemical Co. in 1965, the warranty for fluorocarbon coatings has extended from 10 to over 20 years. A 12-year Florida exposure test confirmed 30% and 80% higher durability than super coatings and conventional coatings respectively.

Specifiction

| Base Material | Pre-coated Aluminum (PE or PVDF base) | Standard Thickness | 0.5mm - 2.0mm |

| Printing Technology | High-Precision Digital UV Printing | Standard Size | Custom panels or coil, limited by printer bed |

| Resolution | Up to 1440 dpi for photorealistic effects | Design Options | Unlimited custom patterns, high-definition images, material replications |

| Protective Top Coat | Transparent PE, PVDF, or Anti-Graffiti Coating | Color Fastness | Excellent, with protective top layer |

Key Features & Highlights

Cost-Effectiveness & Good Performance: Offers the best value for money, providing a quality painted finish with decent durability for general-purpose applications without the premium cost of higher-end coatings.

Excellent Color Retention & Gloss: Formulated to resist color fading and gloss loss under normal outdoor conditions, maintaining a fresh appearance for years in many climates.

Good Formability and Flexibility: The PE coating is relatively flexible, allowing the material to be formed and bent without cracking or peeling, which is ideal for fabricating various profiles and components.

Wide Aesthetic Selection: Available in a vast array of standard and custom colors, along with different gloss levels, to meet diverse design requirements for architectural and industrial projects.

Smooth & Easy-to-Clean Surface: The non-porous, painted surface resists dirt adherence and is easily cleaned with water and mild detergents, ensuring low maintenance.

Application field

Interior Architectural Applications: Ceiling panels, partition walls, and furniture components.

General Outdoor Cladding: Wall panels for warehouses, industrial buildings, and residential sheds in less aggressive environments.

Appliance and Electronics Housings: Cabinets for air conditioners, electrical enclosures, and control boxes.

General Signage and Advertisement: Backplates for indoor and sheltered outdoor signs.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

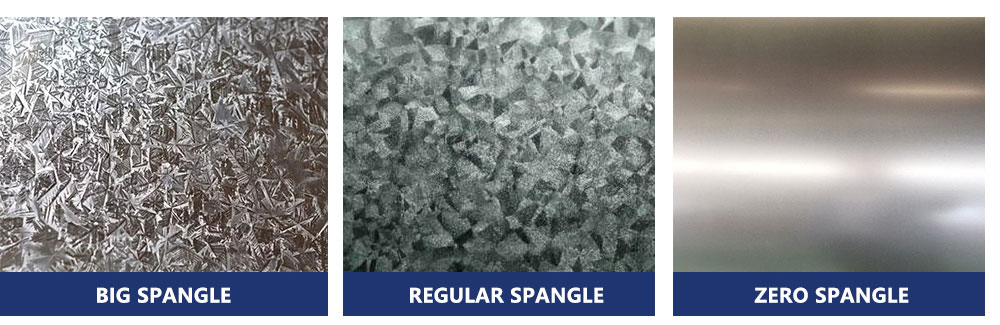

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.

PPAL

Pre-painted aluminium steel Base plate:Aluminium steel Thickness:0.15-1.5mm Width:500-1250mm

Fuorocarbon coating refers to PVDF resin,which mainly refers to coatings made of homopolymers of vinylidene fluoride or copolymers of vi- nylidene fluoride and other small amounts offluorinated vinyl monomers.

The chemical structure of fluoric acidbased materials isbonded byfluorine/carbonization bonds The stability and firmness of this chemical struc: ture make the physical properties of fluorocarbon coatings different from general coatings In adition to excellent mechanical wear resistanceand impactresistance,it also exhibits long-asting resistance to fading and UV radiation,especialy in harsh dimates and environments.Afer high-tem- perature barbecue,the molecular structure of the coating is tightly packed and has weather resistance.

FuoroCarbon coatings can be dwided into two types based on the surace film-forming structure:traditional fluorocarbon coatings and nano flu-

orocarbon costings.In 1965,Penmalt Chemical Company in the United States fist used fluorocarbon coatings to meet the coating requirements

of indoor and outdor aluminum materials in bulildings The wide selection of colors,the dignified appearance of the United states,and durability

added luster to many magnificent curtain wall buildings around the world.The coating manufacturer's guarante for the service life of the coating

starts at 10 years and develops from 15 years to over 2o years.Research institutions in the United Stats have conducted tests and comparisons an

fluorocarbon coatings super coatings,and general catings.Samples costed with fluorocarbon coatings were placed in hot sunlightin Fiorida,U5A,

and exposed to harshenvironments with humid and salinea for 12 years.It has been proven that the stability and durabilityof fluorocarbon coat-

ings are 30 and 80 percentage points higher than the other two coatings.Fluorocarbon coatings ensure thelruse in varlous hash emironments.