Product Overview

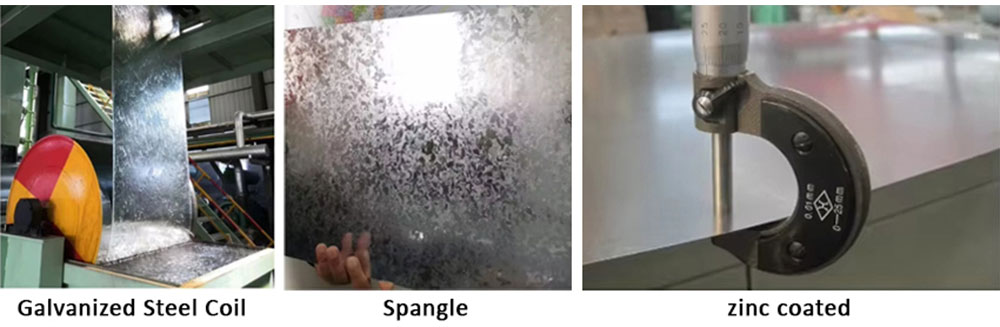

The galvanized sheet produced by our company is coated with a layer of zinc as the main raw material an the surface of the cold-rolled sheet It is widely used in buildng matarials decoration (compositepanels glas tlesrolling dors),daily necesities (washing machines,refrigerators. ovens)And packaging containers,etc.

The company has ecellent equipment configuration and strong technical force.It can produce galvanized steel sheets of various speciications ranging from 0.10 to 1.20×700~1250 ×C.The ultra-thin Large zine gavanized shets produced by 0.10~0.15×1000C are at the international ad- vanced level.Thedomestic gap has an incomparable advantage.

Product Description

This material provides excellent corrosion resistance and long-term color stability. Custom patterns such as wood grain or marble can be achieved through advanced digital printing. Suitable for architectural cladding, interior features, and decorative applications, this eco-friendly product undergoes strict quality testing. Made from 304/316 stainless steel substrate, it ensures structural integrity and UV resistance even in harsh environments. Available in multiple sizes with technical support and custom finish options to meet specific project needs.

Specifiction

Key Features & Highlights

Superior Durability & Longevity: The combination of a robust stainless steel substrate and a hardened protective coating provides excellent resistance to scratches, impacts, corrosion, and UV fading, ensuring a long-lasting, like-new appearance even in harsh environments.

Unmatched Aesthetic Versatility: This technology allows for the application of any color, complex pattern, high-definition image, or even realistic material textures (like wood or marble) onto the metal, offering unparalleled creative freedom for designers and architects.

Enhanced Corrosion & Chemical Resistance: Beyond the natural rust-resistance of stainless steel, the additional color coating layer provides an extra barrier against moisture, salt spray, and mild chemicals, making it ideal for both interior and exterior applications.

Hygienic & Easy Maintenance: The non-porous, seamless surface is extremely easy to clean and disinfect. Options with anti-bacterial properties make it a perfect choice for healthcare, kitchen, and food processing facilities where hygiene is critical.

Eco-Friendly & Sustainable: Stainless steel is 100% recyclable, and the use of environmentally friendly, solvent-free coatings (like UV-cured inks) minimizes VOC emissions, supporting green building initiatives and sustainable design.

Application field

Architectural Cladding & Facades: For creating iconic, colorful, and durable building exteriors and signage.

Interior Design & Decoration: Feature walls, elevator interiors, decorative panels, and custom furniture.

Consumer Electronics & Appliances: Used for high-end kitchen appliances, range hoods, and personal electronics for a premium look and feel.

Public Transportation & Automotive: Interior wall panels and decorative trims in buses, trains, and subway systems.

Medical & Food Industry: Wall cladding, worktops, and equipment surfaces in hospitals, laboratories, and commercial kitchens due to its hygienic properties.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

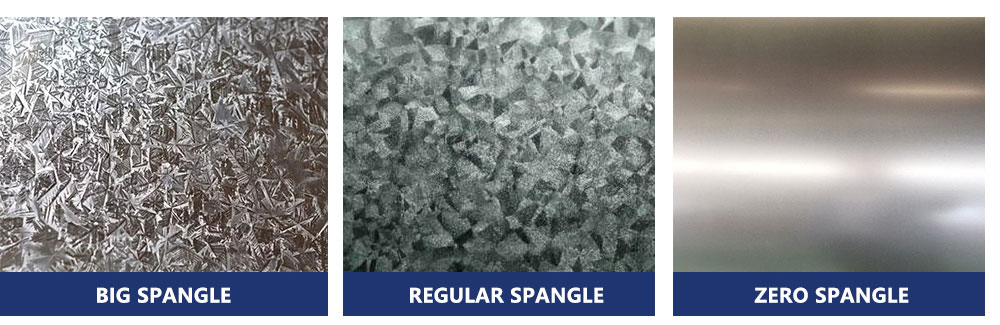

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.